About Us

ABOUT US

Innovation

Quality

Service

Since its establishment, the company has always pursued the concept of "all for customers", and implemented the

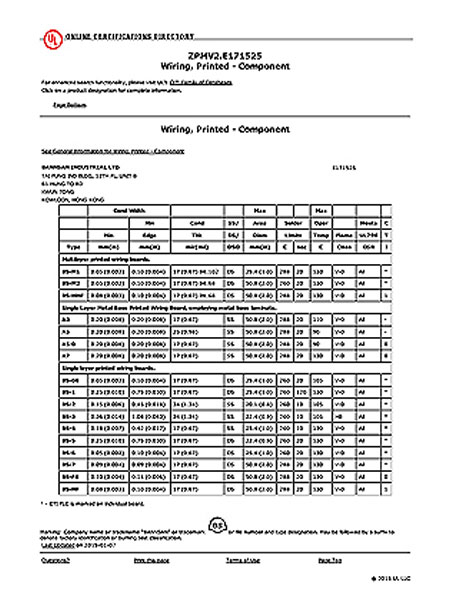

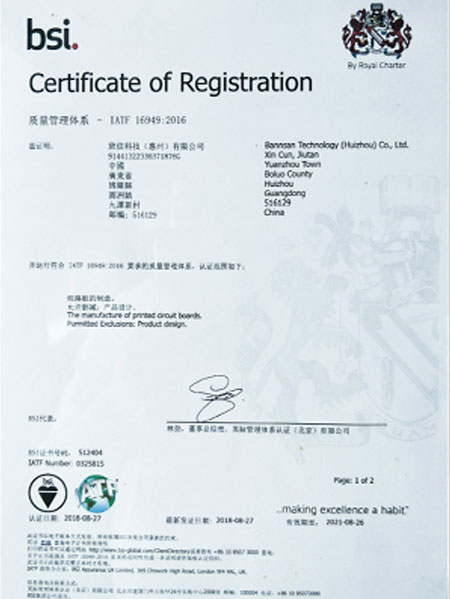

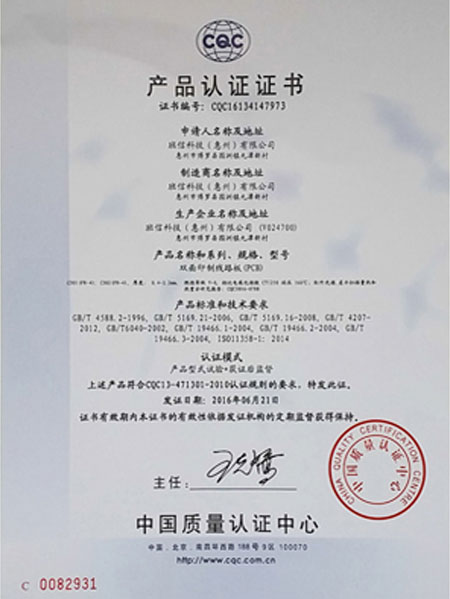

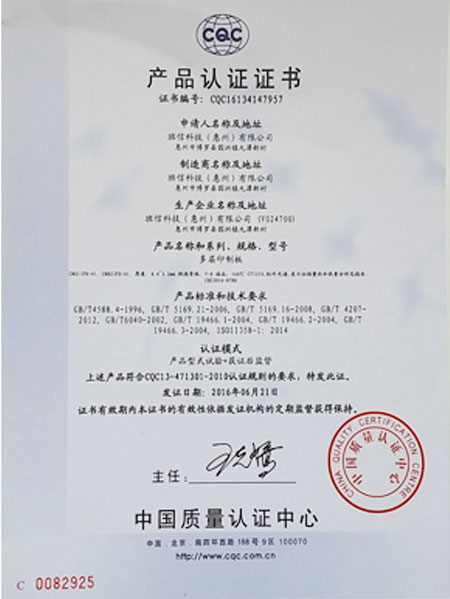

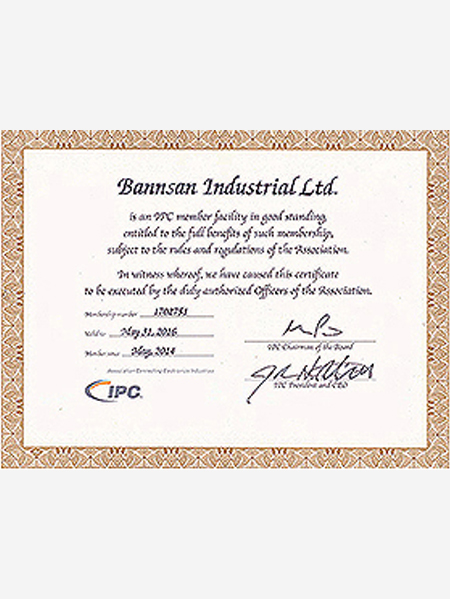

quality policy of "quality awareness as the foundation of survival, customer satisfaction as the symbol of success, excellence as the service purpose, and continuous improvement as the development strategy". It is the driving force that spurs our development, so the company fully implements the ISO14001 environmental assurance system and ISO9001 /TS16949 quality assurance system to ensure that production meets environmental protection requirements and the stable development of product quality. The product safety complies with the American UL standard (E171525), and the product quality complies with the IPC standard and the American military MIL standard, achieving the perfect state of comprehensive quality management. The company also continuously invests in advanced equipment, introduces advanced technology, and constantly strengthens management to improve the company's reputation and enhance customer trust. The purpose is to provide customers with first-class quality, punctual delivery, and reasonable price products and services.

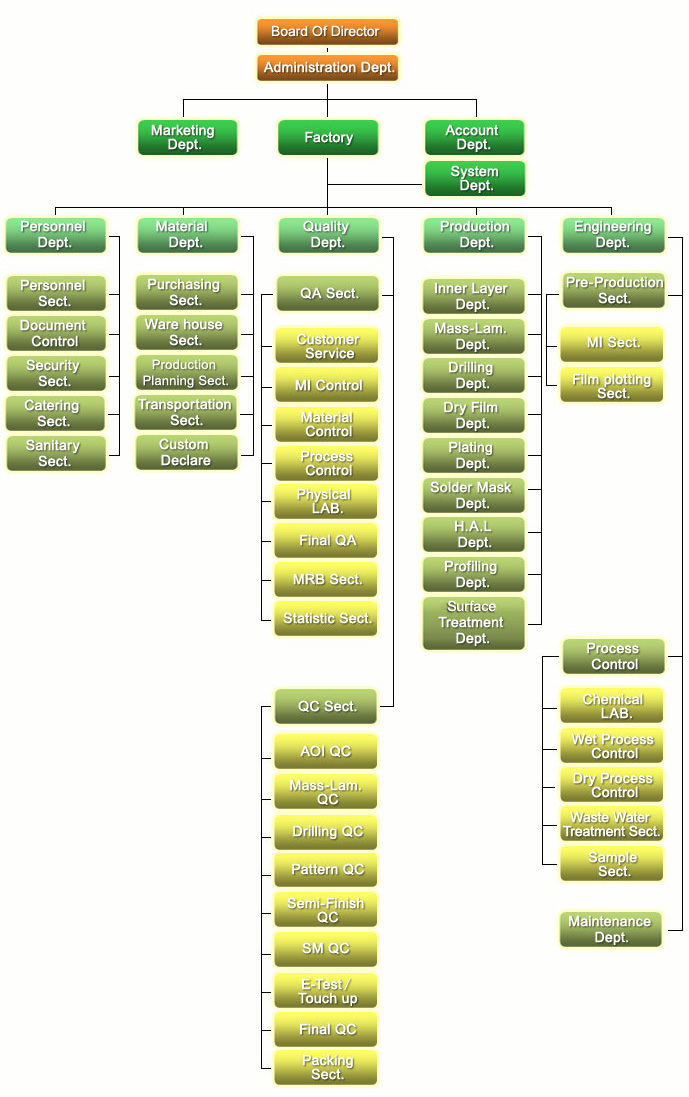

COMPANY STRUCTURE

Company Structure

STRUCTURE

STRUCTURE

Company background

BACKGROUND

30

400

12

60

(SS-00259)

Company background

BACKGROUND

Corporate Culture

CULTURE

Company purpose All for the customer Company Policy

Quality Policy

Environmental Policy

Satisfying Customers is the Indicator of Our Success

Constant Improvement is the Goal of Our Service

Keeping Improvement is Our Strategy to Develop

Comply with the Laws to Take Precautions against Pollution

Enhance Process Management to Lower the Loss

Continue Improving to Keep Beautiful Environment